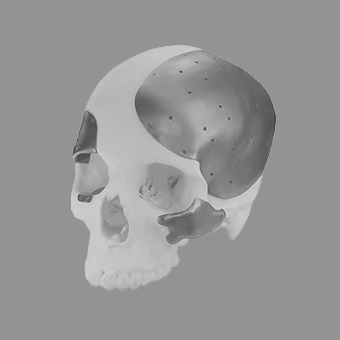

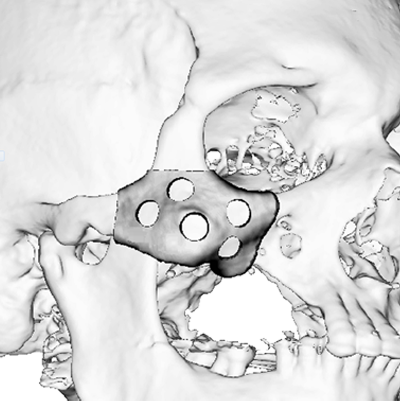

Medical-grade PEEK PSI

- Offers proven biocompatibility and biostability

- Closely matches the strength of the bone

- Is radiolucent

- Can be easily modified in surgery (e.g. if you wanted to add screws, monitoring devices, or drainage)

- Raw material carefully sourced in Europe and the UK